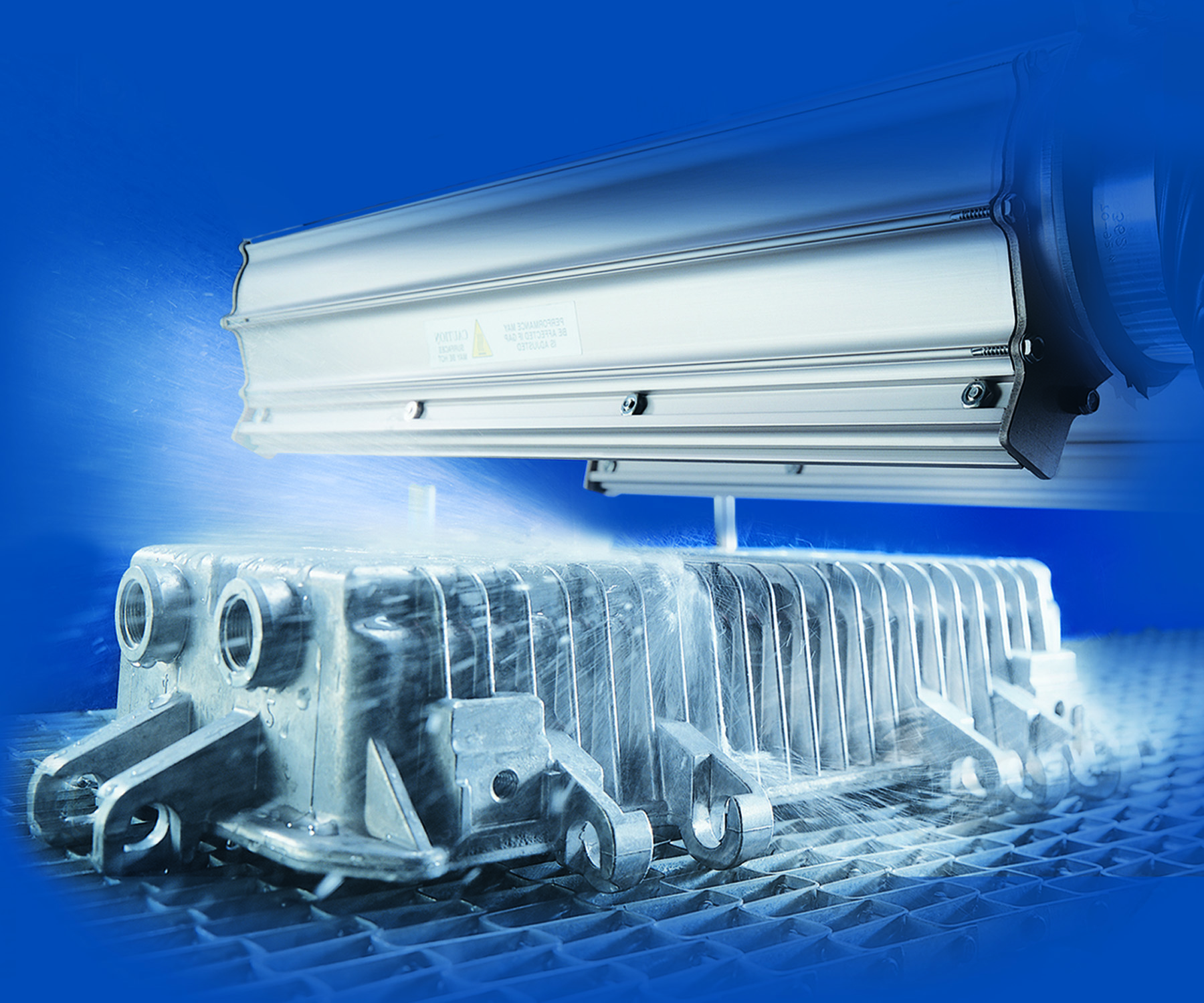

Revolutionary Air Knife Drying Systems for Energy-Efficient Automotive Components Manufacturing Processes Discover cutting-edge blower and air knife solutions meticulously crafted to meet the diverse needs of automotive components manufacturing.

Our High velocity high-efficient air knife drying systems are engineered to meet the burgeoning demands of the industry, addressing requirements for heightened quality, expedited production, automation, and eco-consciousness. At Nexgen Drying, our state-of-the-art blower and air knife drying systems are useful to blow off water particles,dust,dirt, loose bur particles from over all the surfaces in various manufacturing processes including machining, cleaning, cooling, plating, and painting. Moreover, they deliver high-velocity air for static control, pressurized air cooling, and facilitating high- volume flow bench testing of engine components.

Our Usps

Nexgen Drying proudly presents air knife drying systems meticulously designed for:

Elevate your automotive components manufacturing processes with Nexgen Drying’s innovative solutions, where efficiency meets sustainability.